Investing in quality tools

Good ‘work’ is rarely cheap. Cheap ‘work’ is rarely good. If we swap the word ‘work’ for ‘tools’ we realise that tradespeople and us, we’re peas in a pod. We don’t want to make tools that aren’t any good. So we make the best tools possible. This means coming up with the best designs, using the best materials and investing in the best manufacturing processes.

This all comes at a price and it’s why our customers tend to be those that have been in the trades for years. They’ve had experience of using mass produced or cheap tools, and decide that they want to invest in hand tools from a company that actually cares about the tools they make and the people that use them. If you understand the value of providing high quality work for your customers, you’ll understand the value of making high quality tools and the associated costs in doing so.

TrigJig Tools was founded by Dan Soanes-Brown, an ex-tradesperson, after some time outside of the construction industry he had an idea for a tool and set up a business to sell them. However, he quickly found that there were very few companies left in the UK capable of making good quality hand tools. Even well-known brands from the USA, Germany and other traditional manufacturing powerhouses had sold up and moved their manufacturing to the far east.

TrigJig saw this as an opportunity. Whilst offshoring manufacturing was beneficial for company owners that saw increased profits, the quality of tools was inevitably compromised and people saw tool life shrink from decades to months.

So TrigJig set out on a mission to reverse this. How many times have you been in your Dad’s workshop and found 50 year old hand tools that still function? How about those cheap alternatives you find on Amazon or eBay? Will they still be put to good use in 4 years time?

We knew that those tradespeople taking great pride in their work, skills and profession would prefer to spend money on tools that last, and built by a company that wouldn’t abandon customers as soon as they had parted with their cash.

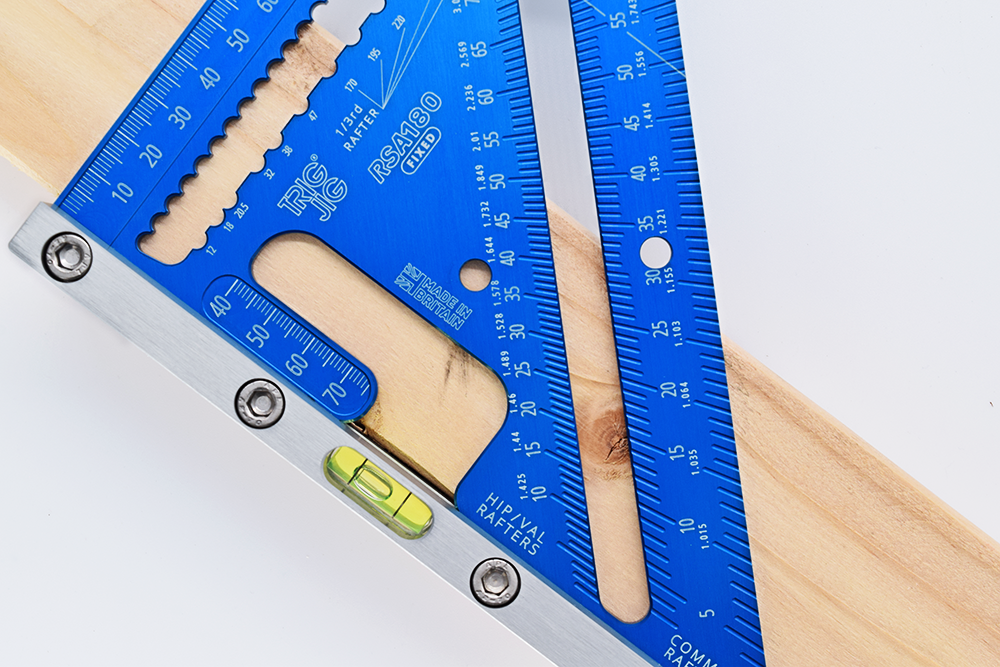

So we invested in a small team, rented a new workshop, bought design workstations, purchased specialist manufacturing machinery and set about building the best hand tool brand anyone had seen in decades!

Every tool we design MUST be unique or simply be better than anything else out there. We’re constantly innovating and improving and striving to make better tools. We chat to our regular customers to see what they want from our future tools and really value and appreciate their feedback. These aren’t just words. We understand that businesses need customers to buy just as much as customers need businesses to buy from. It’s a mutualistic relationship that we work hard to nurture. How many amazon sellers and mass produced re-badged tool makers will offer the same?

Leave a comment